Home ﹥ Product Features > Instant Cooking and Food Vending & E-Commerce System > Robotic Arm Noodle Cooking Line (with Noodle Maker + Broth Machine) (POS Compatible) > Future-Ready Smart Noodle Workstation

Future-Ready Smart Noodle Workstation

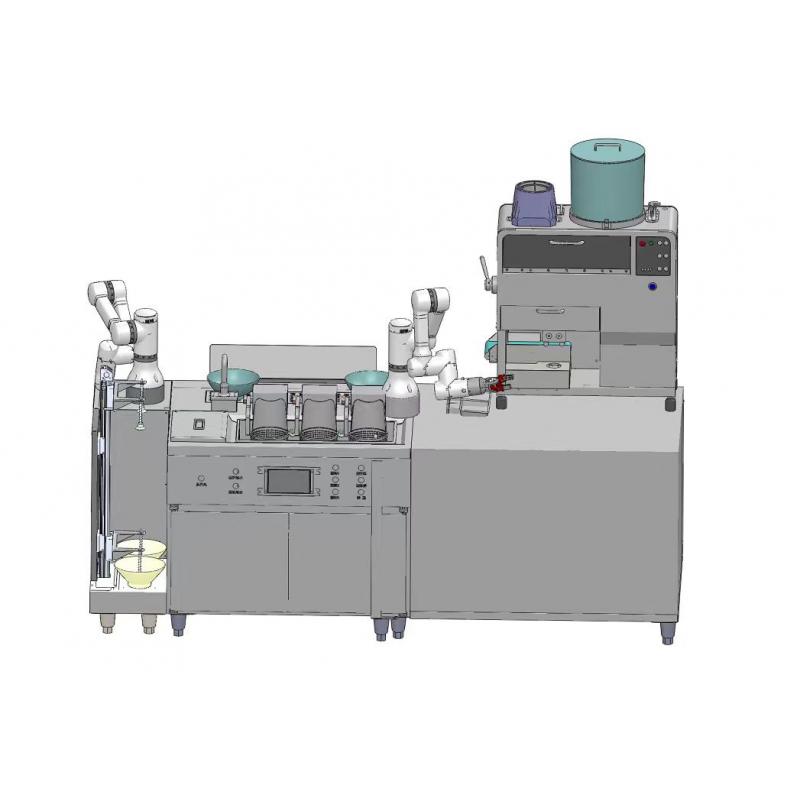

The smart system showcased in the images you provided is not just a piece of equipment. It represents a fully operational smart noodle cooking system, integrating collaborative robotic arm technology, a commercial noodle cooker, multi-basket cooking modules, a vertical ingredient storage rack, and a streamlined one-piece stainless steel cooking platform

The New Benchmark of Foodservice Automation

In today’s fast-shifting foodservice industry, efficiency, consistency, and operational scalability are no longer optional—they define the competitive edge. As labor shortages become a structural challenge and customer expectations for quality and speed continue to rise, the industry is accelerating toward restaurant automation equipment, smart kitchen systems, and resilient, standardized workflows.

The smart system showcased in the images you provided is not just a piece of equipment. It represents a fully operational smart noodle cooking system, integrating collaborative robotic arm technology, a commercial noodle cooker, multi-basket cooking modules, a vertical ingredient storage rack, and a streamlined one-piece stainless steel cooking platform.

This is not a concept.

It is a future-ready intelligent noodle workstation designed for real foodservice environments.

1. Industrial-Grade Aesthetics, Front-End Operational Power

A first glance at the workstation reveals intentional engineering:

● A stainless steel cooking platform engineered to support long-hour commercial operations

● A vertical ingredient storage rack with transparent visibility for food safety and refill management

● A multi-basket noodle cooker enabling simultaneous cooking cycles

● A smart soup dispensing platform that accelerates service flow

● A lower-level automated bowl management zone for rapid replenishment

● A collaborative robotic arm system executing precise grabbing, transferring, and positioning movements

Every module visible in the image reinforces one message:

This is a front-of-house automation system built not only for efficiency, but for customer-facing appeal.

The aesthetic consistency of the design naturally elevates the dining environment, functioning as a technology-enhanced dining experience for guests—especially in hotel breakfast noodle stations, buffet noodle stations, and foodservice automation showcase environments.

2. Consistency Is Profit: Why Standardization Wins

The biggest operational pain point in foodservice is not just speed—it’s inconsistency.

The smart noodle cooking system solves this by establishing repeatable, robot-driven processes:

● The robotic arm ensures standardized restaurant operations

● The multi-zone cooking platform delivers high-efficiency noodle modules

● Automated basket handling reduces human error

● Soup dispensing becomes an exact, controlled action

● Ingredient visibility improves refill planning and reduces downtime

This creates a workflow that is not dependent on staff experience or variable performance.

It is a system that gives operators the power to deliver the same quality, every time, even during peak-hour restaurant efficiency windows.

For multi-location businesses, this means:

✔ Easier staff training

✔ Better quality control

✔ Predictable operating costs

✔ Scalable brand value

This is the essence of restaurant workflow standardization.

3. Automation as the Answer to Labor Shortages

The modern kitchen is no longer defined by the number of staff it employs,

but by how intelligently those staff are supported.

The system shown in your photos directly addresses the industry’s structural labor shortage by automating the most repetitive, time-consuming, fatigue-inducing tasks:

● noodle grabbing

● basket placing

● timing control

● soup dispensing

● bowl replenishment

This transforms the traditional noodle station into a hybrid manual–robot cooking station, where human workers focus on customer interaction, plating, or other higher-value tasks.

For operators, this is not merely automation—it is a labor shortage restaurant solution that ensures business continuity even during tight labor markets.

4. Modular Engineering: One Station, Multiple Applications

The CAD drawings clearly reveal one crucial advantage:

This workstation is fundamentally modular.

Every visible component—from the vertical ingredient rack to the multi-zone noodle cooker—shows that the system can be reconfigured to fit different commercial environments:

● Large-scale kitchen system integration

● Smart kitchen appliance integration

● Restaurant chain deployments

● Buffet noodle station expansion

● Hotel breakfast noodle station layouts

● Noodle preparation self-service units

This extensibility future-proofs your investment and allows the same workstation to adapt as your business evolves.

For foodservice brands seeking consistency across outlets, this becomes a smart kitchen equipment platform, not just a standalone machine.

5. When Technology Becomes Branding

Consumers today don’t just eat—they experience, record, and share.

A robotic system functioning within a dining area becomes:

✔ a visual landmark

✔ a conversation driver

✔ a reason for guests to record content

✔ a signature element of the brand identity

In other words, the workstation becomes a technology-driven restaurant branding asset.

Whether in hotels, retail dining spaces, or modern buffets, this smart noodle workstation effortlessly upgrades the brand’s market perception—and the images you provided clearly show this premium aura.

This is why technology-enhanced stations are becoming central pieces in premium dining automation strategies across Asia.

6. Enterprise View 2025–2027: A Strategic Investment

From the actual images and hardware layout, it is evident that the system is already mature enough for deployment—not a prototype, not a concept, but a fully functional installation.

For enterprise operators, this means:

● operational risks are reduced

● rollout speed increases

● staff training becomes predictable

● customer experience becomes repeatable

● supply planning becomes more accurate

The real strategic value lies in its ability to support:

● smart dining environment design

● automated commercial kitchen workflow

● high-traffic kitchen solutions

● standardized meal output equipment

● scalable brand formats

In a market where foodservice brands fight on thin margins and unpredictable staff performance, a system like this becomes the backbone of long-term restaurant efficiency enhancement.

**Conclusion:

Automation Is Not About Replacing People—It’s About Elevating Value**

Everything visible in your photos—the robotic noodle cooking station, multi-basket noodle cooker, smart soup dispensing platform, automated bowl management, and vertical ingredient storage rack—reflects a singular mission:

To create a foodservice environment where quality, speed, and consistency are no longer variables, but guarantees.

This is the future of automated dining.

And this workstation is the entry point to that future.